Experience the new compact class with the TX 6 series

20.03.2023

Start of the new series of traysealer models from MULTIVAC

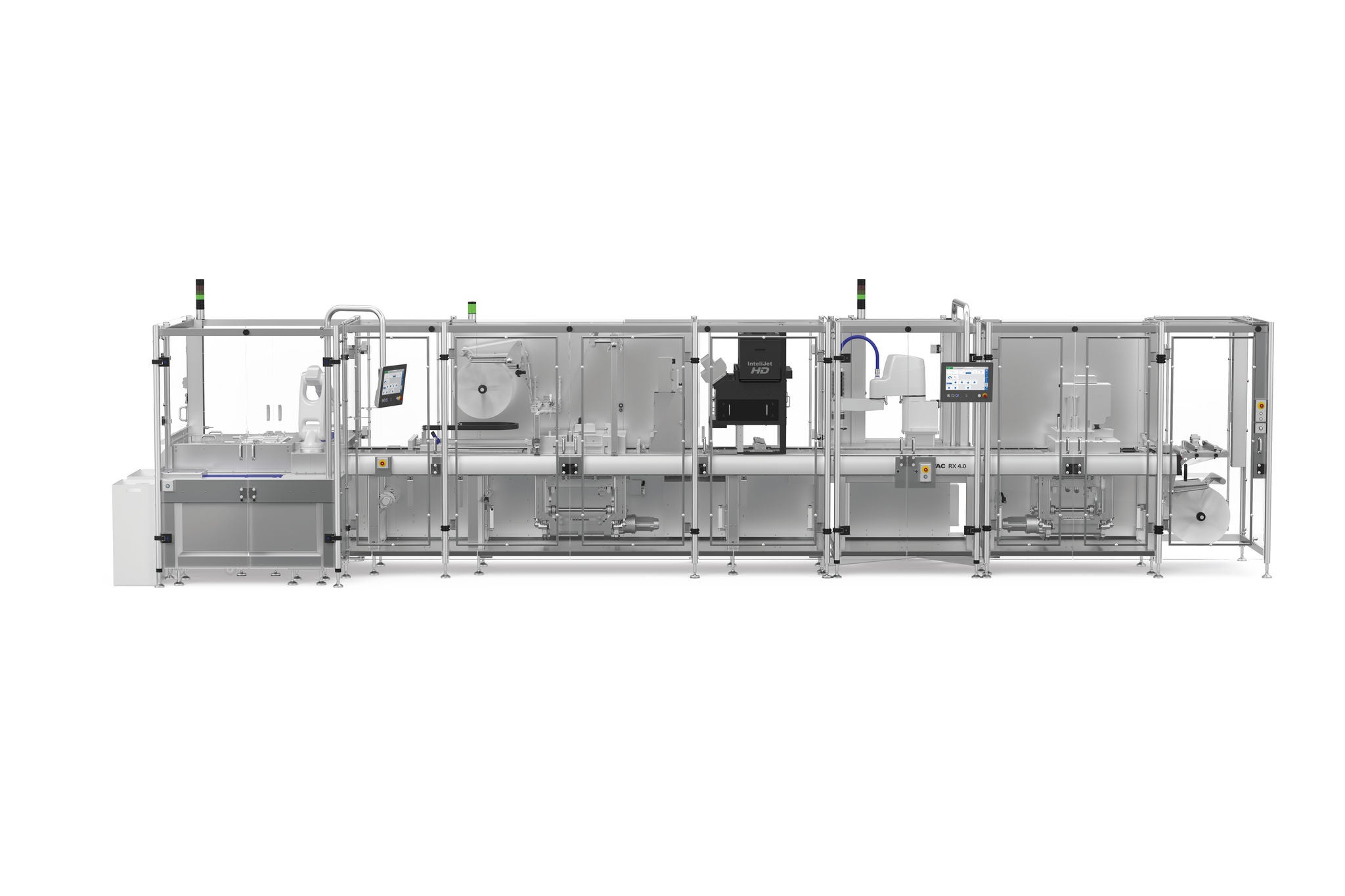

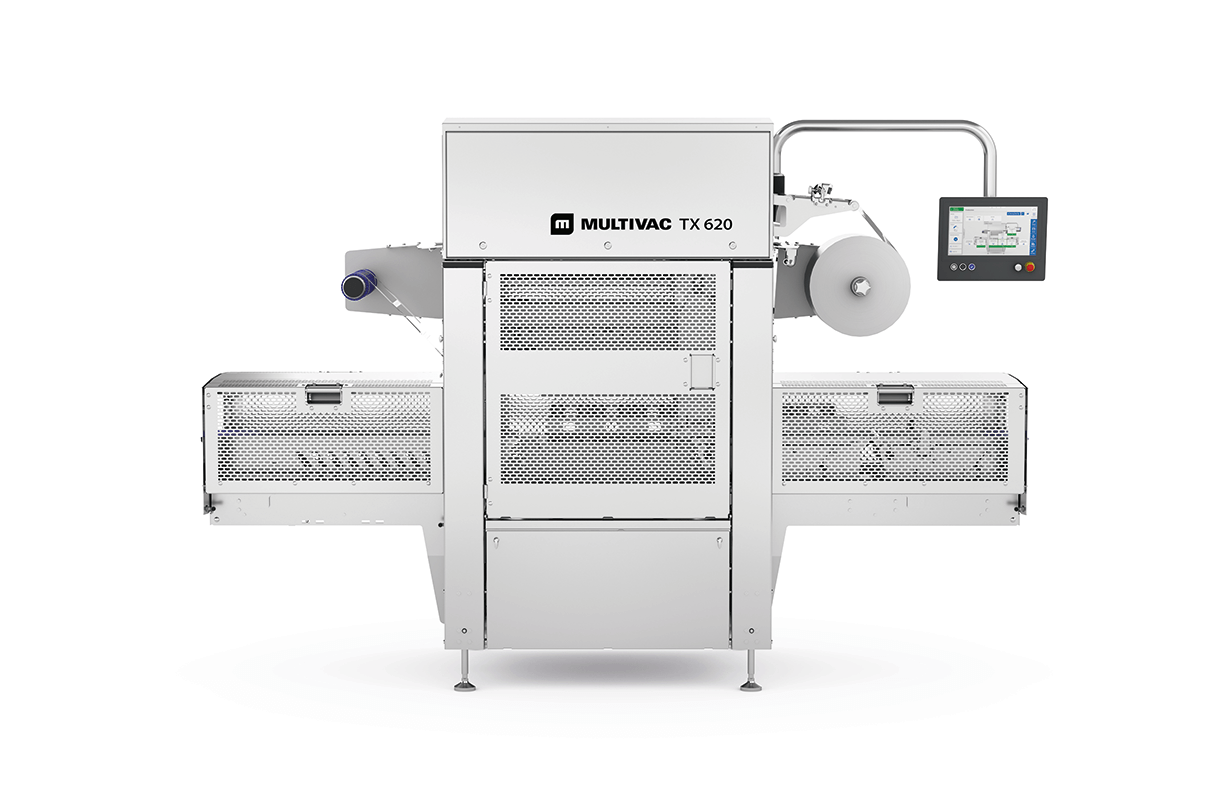

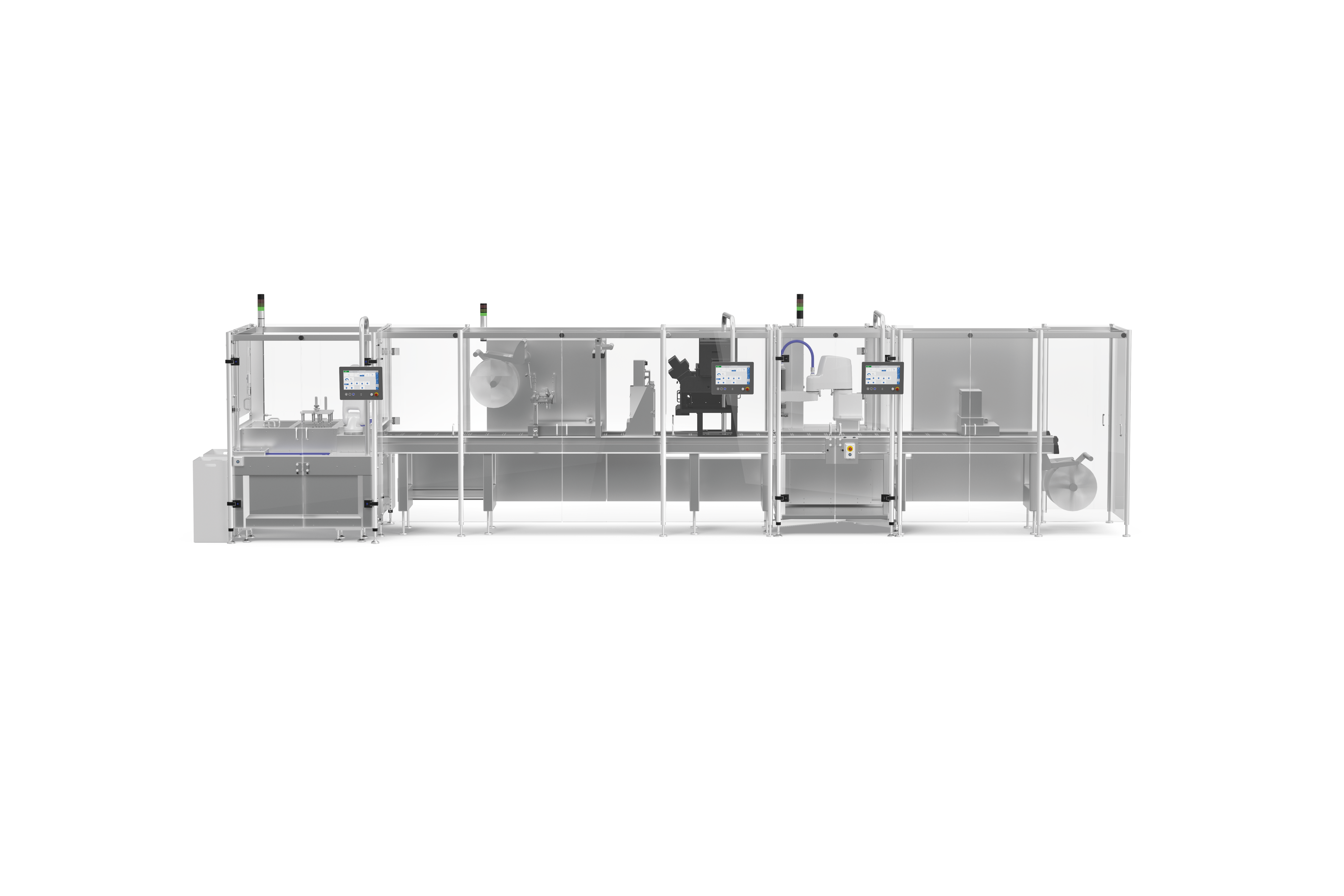

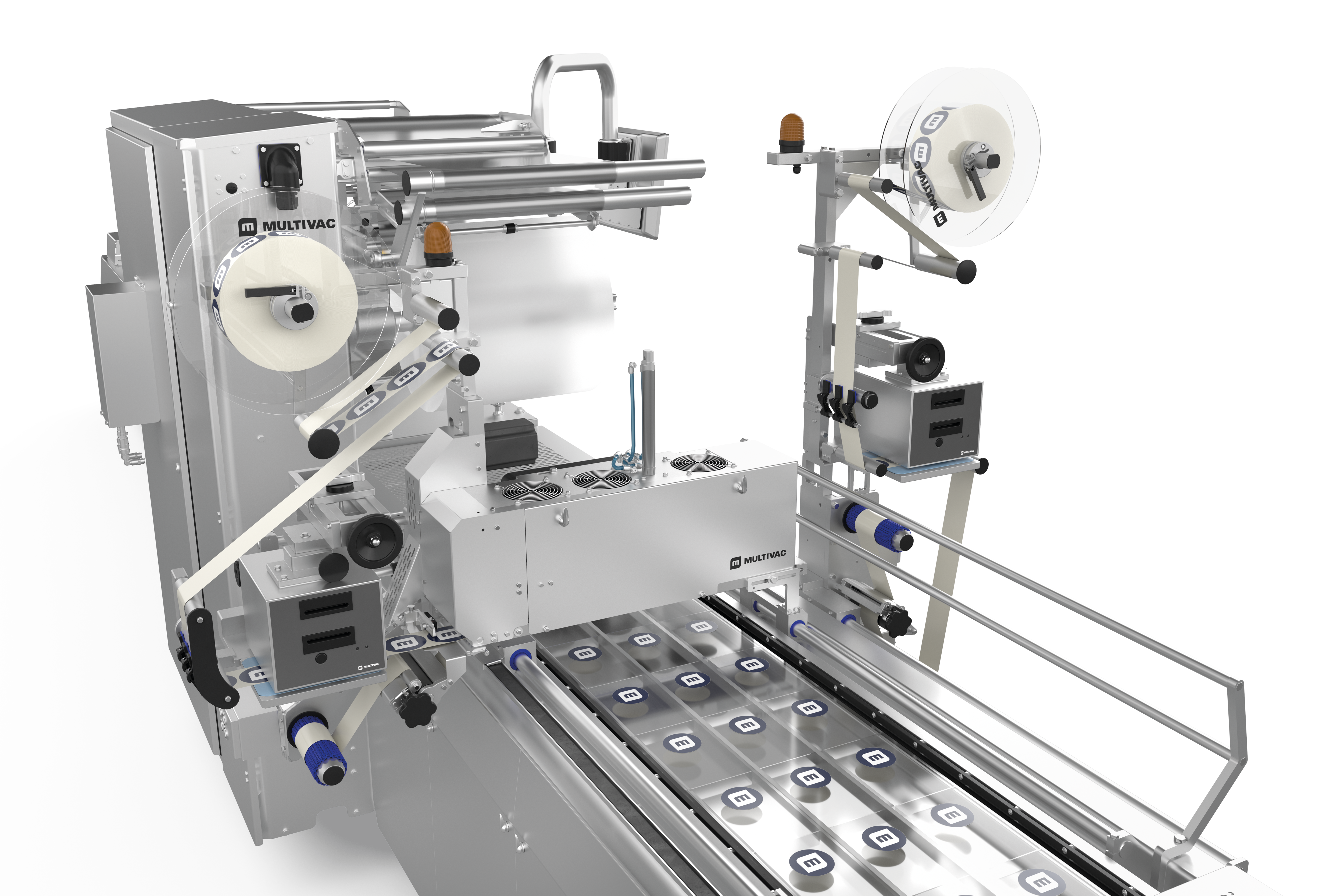

Wolfertschwenden, 20 March 2023 - Compact, versatile, networked: The new MULTIVAC traysealers are highly impressive in their outstanding performance with exceptionally efficient use of the available production space. Just like the existing high-output TX 7 and TX 8 series, the space-saving new arrivals in the product range offer everything that customers could expect from a trend-setting machine generation. Also in terms of reliability, hygiene and ease of operation.

These compact traysealers are coming at just the right time in view of the current economic challenges and the associated explosion in costs. “Thanks to their small footprint, they make a major contribution to increasing output in the smallest of spaces - and all this on a very sustainable, flexible and cost-attractive basis,” says Franziska Schreiber, Product Manager at MULTIVAC. The specialist packaging company has now completed its product range in the TX class, which began its success story in 2019 with the fully automatic TX 710.

Performance at the highest level

These new models, which were developed with rapid product change and high cycle output for a wide range of applications, are inspirational in their technical features with intelligent machine and line control, their high standard of hygiene, and of course their usual reliability. They can be easily integrated into a wide range of production environments thanks to their compact construction - and even designed as a two-track solution for still greater efficiency.

Both models are equipped with robust servo drives, which guarantee maximum speed and gentle product handling over the long term. The intelligent machine control and state-of-the-art die concept, the so-called X-tools, ensure that the investment in these models is always future-proof. Particularly since both the TX 610 and TX 620 are designed for use with MULTIVAC Smart Services and MULTIVAC Line Control - both of which are tools for providing maximum transparency and very efficient line operation.

When compared with the existing TX range available in the market, the TX 6 series has been completely redeveloped with the aim of producing a compact and cost-effective solution. “The design language, functionality and areas of application are however based on their bigger brothers, the TX 7 and TX 8 series,” emphasizes Franziska Schreiber. What distinguishes the TX 610 from the TX 620 is essentially the machine length and the usable size of the die.

Sustainability with potential for the future

The compact traysealers have been systematically designed for sustainability: Firstly, their long lifespan is an important factor in this context, and secondly depending on the application, there is no requirement at all for compressed air or cooling water - and this makes an active contribution to saving resources.

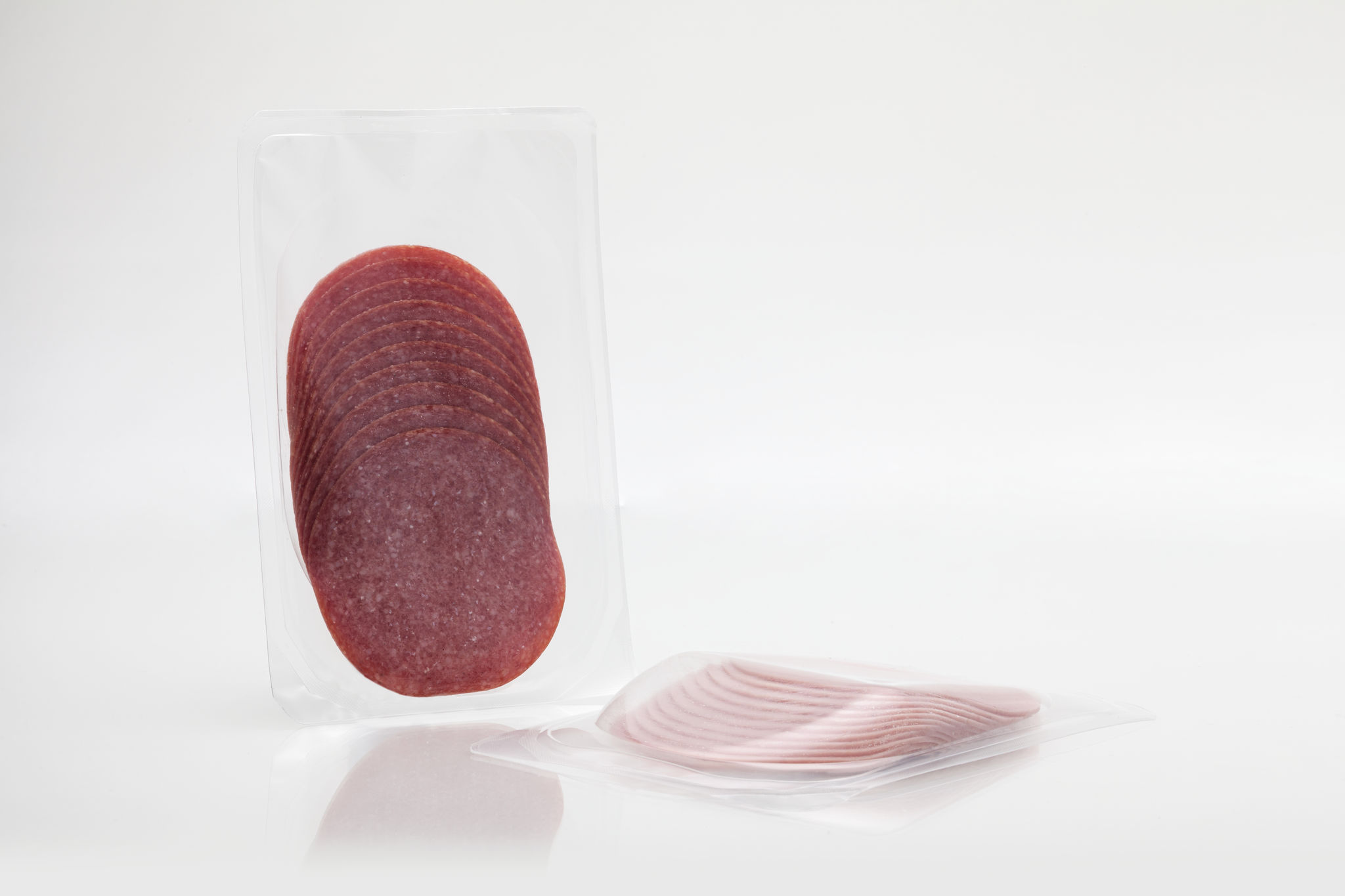

The machines can run trays from a wide range of materials very reliably and without any limitations, and these include for example paper- and fibre-based materials as well as plastics. The range of applications extends from "Sealing only" through to Modified Atmosphere Packaging and right up to MultiFresh vacuum skin packs.

Ease of operation with a high level of process reliability

The clear operating concept of the TX 6 series provides for logical process sequences, significantly reducing the opportunities for incorrect operation. The intuitive HMI makes controlling the machine much easier, since many pack and process parameters are already configured and can be called up very quickly.

The conversion of the machines to different pack formats without the need for tools also makes a major contribution to efficiency and safety - just like the simple cleaning and maintenance, since all the machine components are easily accessible.

“Thanks to the launch of the TX compact class ...

... we are able to fully satisfy the rising demand for compact tray packaging solutions, which are required to increase production efficiency in the smallest of spaces. Since the TX 6 series with its minimal footprint sets the benchmark in this class in terms of reliability, flexibility and future-proofing, MULTIVAC is making good on its promise with this new product family as well,” says Franziska Schreiber.

- Size

- 91 KB

- Format

- Size

- 162 KB

- Format

- png

Aktuelle News

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com