MULTIVAC will be presenting an expanded range of cross web labellers at Anuga FoodTec

12.02.2024

Innovative solution for closure sealing of trays

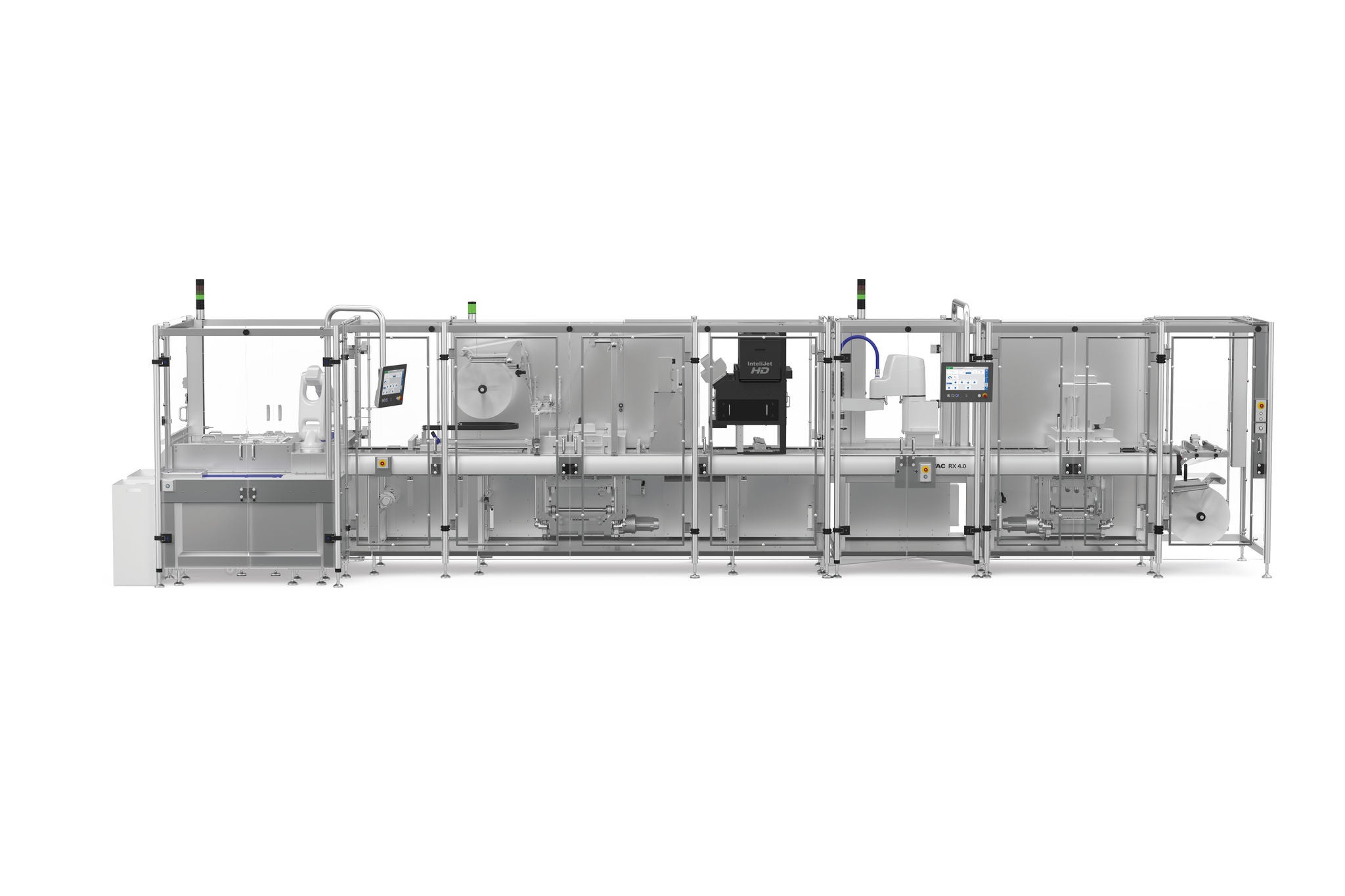

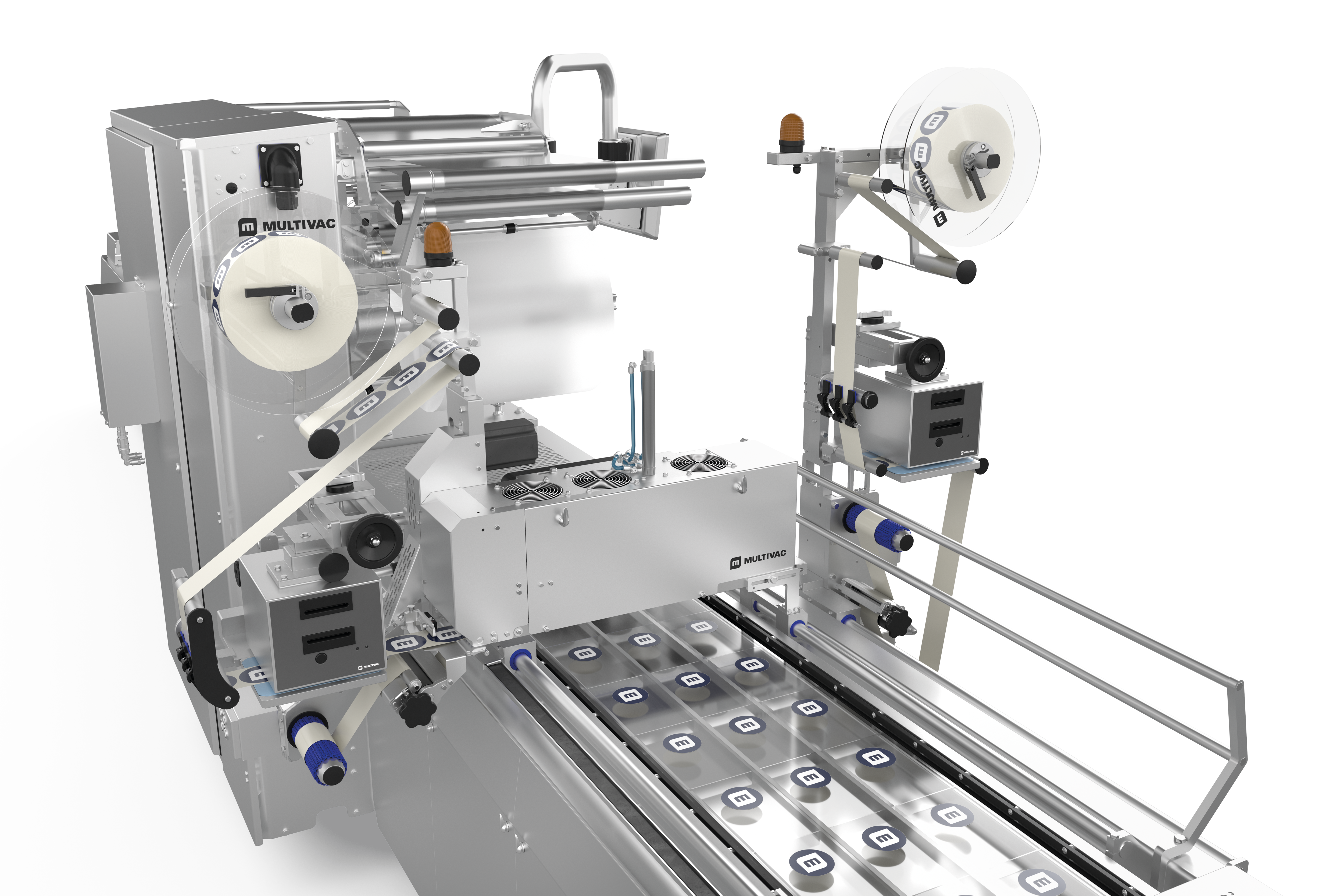

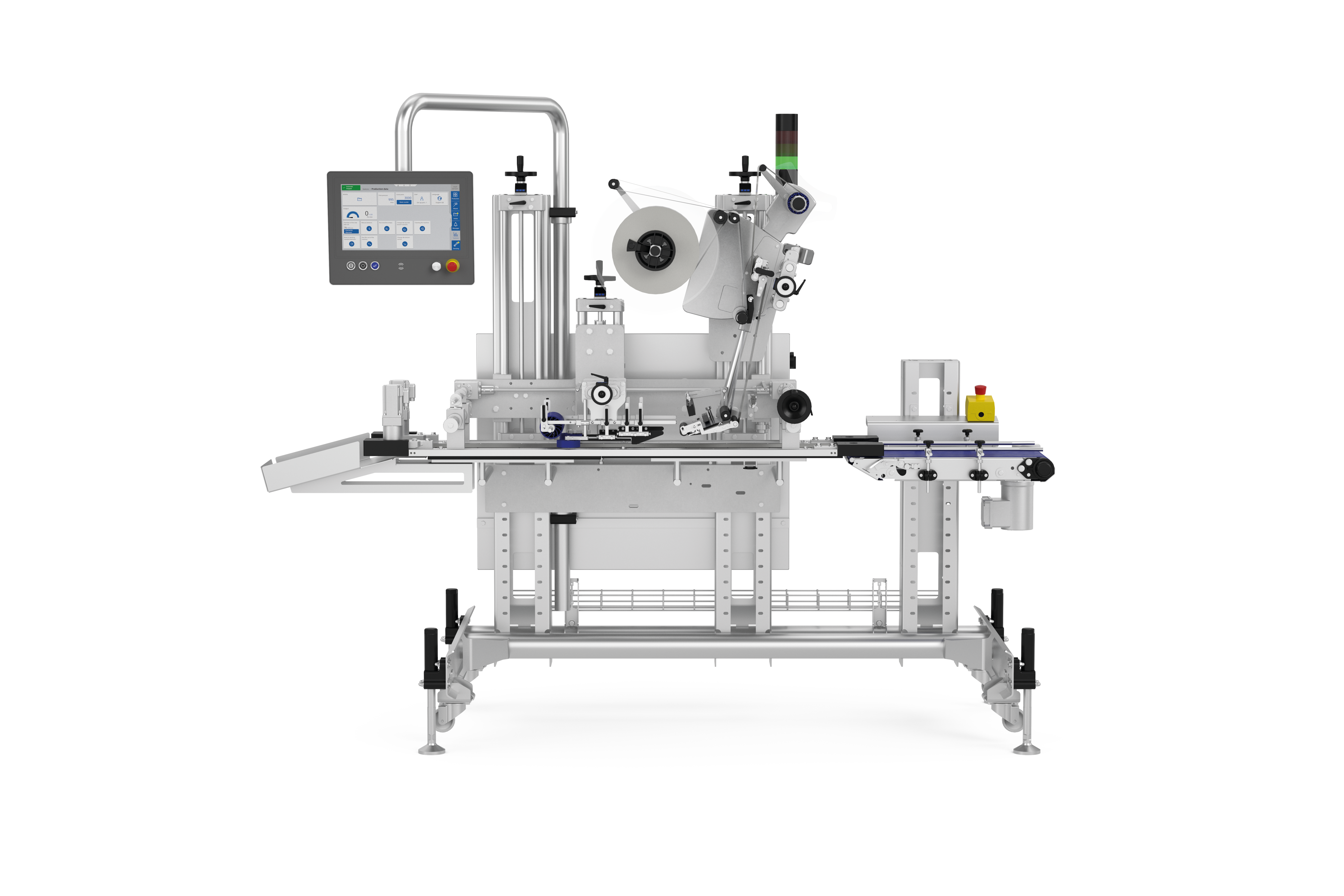

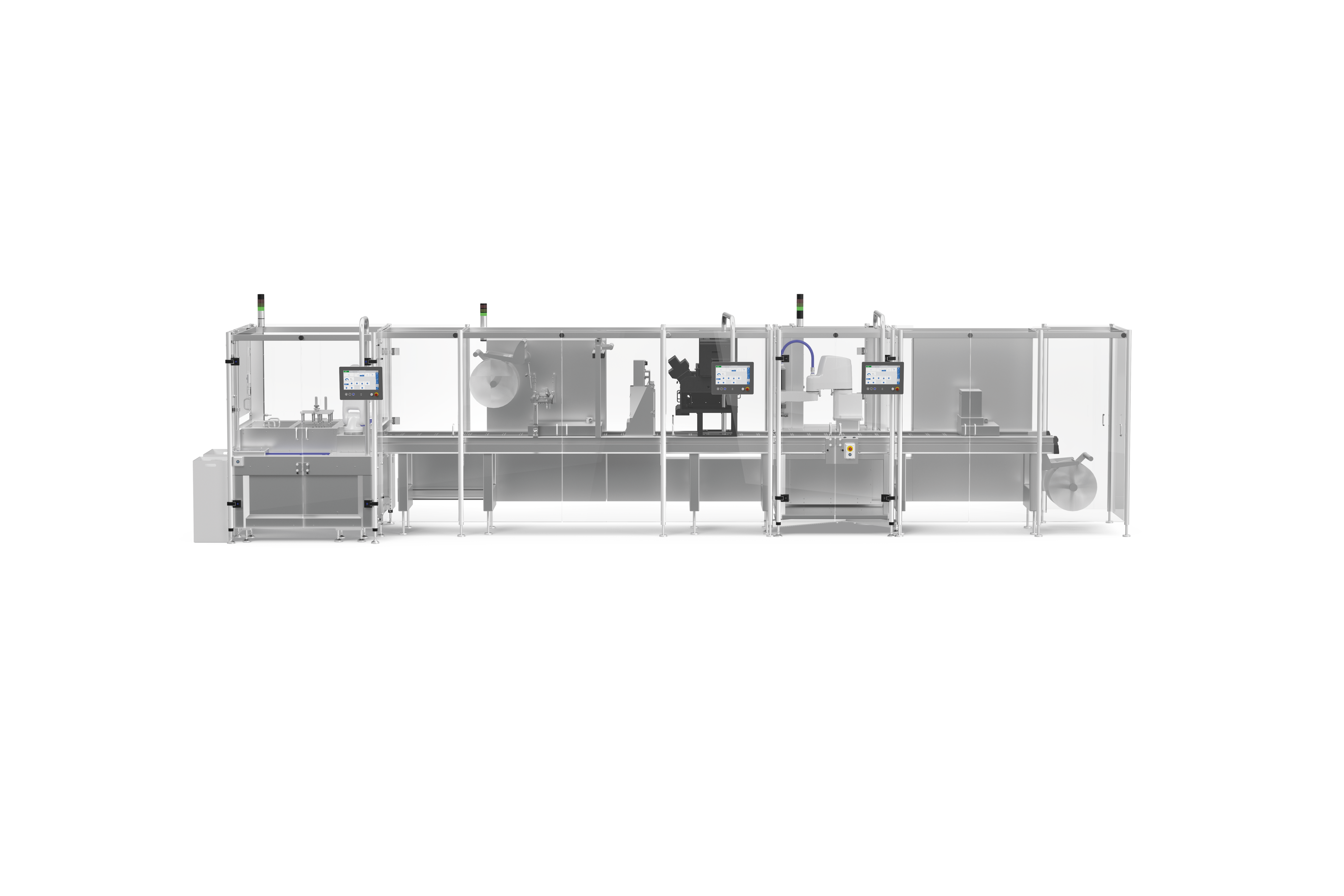

Wolfertschwenden, 12 February 2024 – Using the MULTIVAC TopCLOSETM process on a labeller, trays can be sealed closed simply, sustainably and attractively by means of self-adhesive labels – and completely without a packaging machine. MULTIVAC will be showing how this automatic process works, using a L 330 conveyor belt labeller at Anuga FoodTec (Hall 8.1, Stand C10).

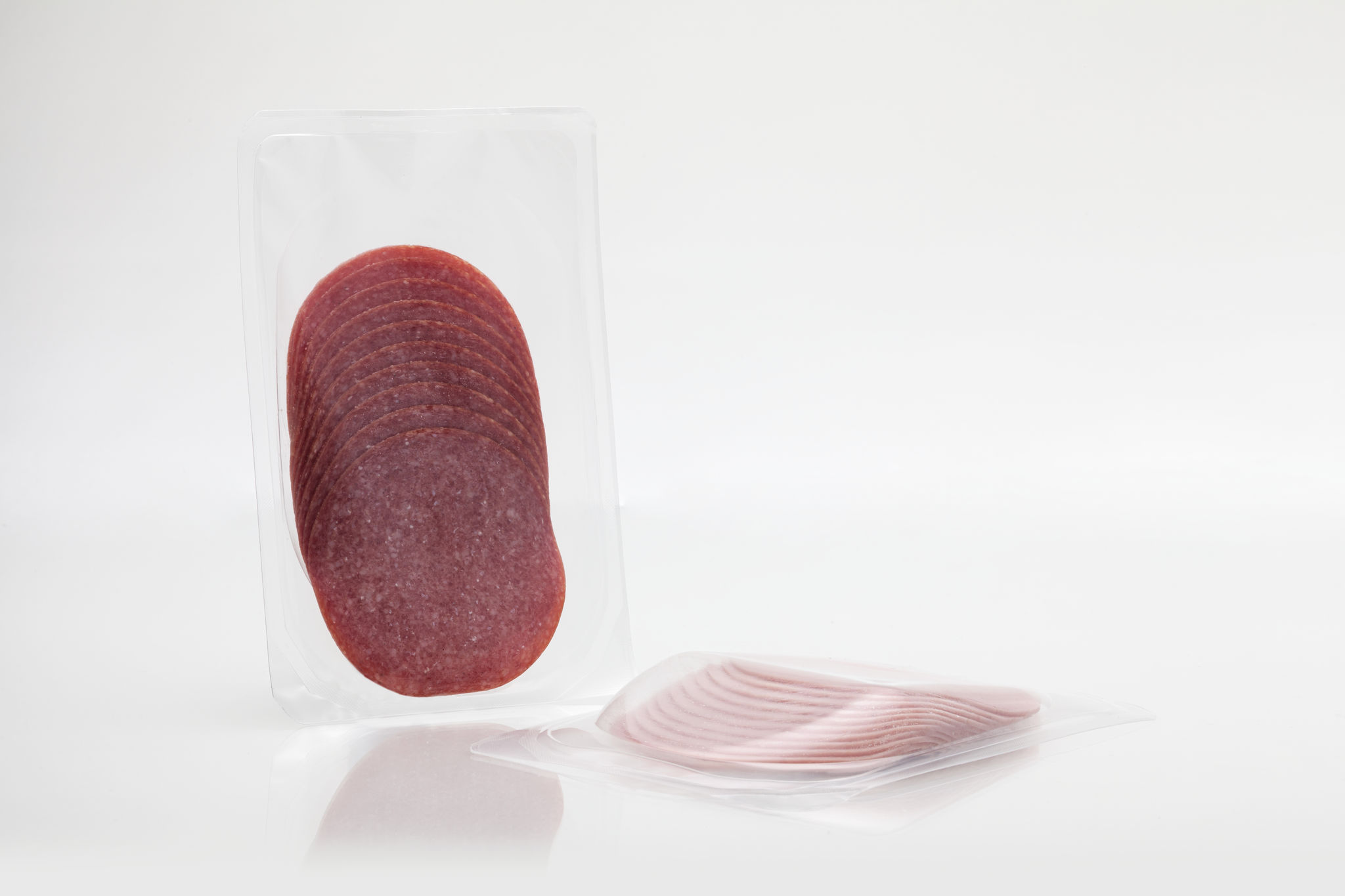

If fruit and vegetables do not require to be packed under modified atmosphere or airtight in a vacuum, self-adhesive labels are the ideal opportunity to secure the content of the tray against falling out or being removed. Thanks to a special manufacturing process, MULTIVAC TopCLOSETM labels have adhesive-free zones on the inside of the labels, so that they are permitted for direct contact with food. They can be equipped with a tear flap and a reseal feature, and they are suitable for both right-angled and round trays.

The MULTIVAC TopCLOSETM process is performed on the L 330 conveyor belt labeller, and it is possible to print the labels with variable data, as well as subsequently inspecting the label print. The label seals the tray closed automatically on the run, after the trays have been fed in manually or transferred from an upstream module. The conveyor belt labeller can be adapted to different tray sizes and shapes very quickly and easily without the use of any tools. And converting to alternative products, or inserting new label rolls, also involves only the minimum downtime, since the labeller can be set very conveniently thanks to its position displays, which are operated intuitively.

“The high-performance L 330 conveyor belt labeller can save costs, when compared with labour-intensive, manual solutions or automatic packaging machines, and it can achieve closure sealing of up to 250 packs per minute,” explains Ronald Helmel, Business Development Manager at MULTIVAC Marking & Inspection. “This also means that food wastage is reduced to a minimum. In addition to this, a zero-downtime version is available for uninterrupted labelling, as well as various automation options such as denesters or product infeed and discharge units.“

Experience the MULTIVAC TopCLOSE™ process at Anuga FoodTec

At the trade fair MULTIVAC will be showing the TopCLOSETM process, using a film label with a transparent viewing window for the closure sealing of berries in a cardboard tray. “The proportion of plastic in the pack is under ten percent. Cut-outs in the label provide the necessary air circulation, to ensure that the optimum shelf life for the berries is achieved,” says Ronald Helmel.

- Size

- 88 KB

- Format

- Size

- 6 MB

- Format

- png

Latest News

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com